What is Dry Ice Blasting

Benefits of Dry Ice Blasting

Decreased Downtime through Cleaning In-Place

Typical cleaning procedures require that equipment be disassembled and moved to an assigned area for proper cleaning. That is not the case with dry ice blasting. Equipment can be cleaned in-place and hot in most situations. Because of that, many time-consuming, labor-intensive steps which were required with other methods such as sand blasting can be eliminated. For example, equipment does not need cool down time, disassembly, relocation, reassembly and warm up time. This can shorten the downtime for cleaning equipment from days down to hours.

Faster and More Thorough Cleaning

With dry ice blast cleaning, a superior clean can be achieved while reducing hours when compared to scrubbing with abrasive pads or wire brushes. A tremendous labour savings is accomplished. In addition, the CO2 blasting method cleans in crevices that can't be reached by hand. As a result, equipment runs more efficiently and potential leaks are revealed possibly preventing major system failures.

Less Equipment Damage

Dry ice blasting often eliminates equipment damage. Cleaning methods such as sandblasting leave an aggressive and abrasive effect on the surface. They can actually remove part of the surface, changing the surface structure considerably. Dry ice is non-abrasive to surfaces and does not change a surface's structure. It lifts the contaminants away. Second, because equipment can now be cleaned in place, potential damage from moving equipment to and from a dedicated cleaning area is also eliminated.

Reduction or Elimination of Solvents

Dry ice blasting uses no solvents, but instead uses harmless CO2 pellets. This can be a critical need for certain companies in order to comply with environmental regulations or to improve worker safety. There are no issues pertaining to toxicity with CO2 blasting.

Reduced Waste Disposal

With other cleaning methods, whether it be with solvents, sand blasting or some other means, the cleaning agent becomes a secondary contaminant and must be disposed of as toxic waste along with the primary contaminant. However, with dry ice blast cleaning because the CO2 pellet vaporizes upon contact, the only waste created is the contaminant itself. This alone can result in significant waste reduction.

Increased Safety

Dry ice blasting pellets are non-toxic, non-hazardous creating advantages to the environment, your employees, and production facility. There is no secondary waste associated with dry ice blasting. The procedure is safe for workers, does not damage equipment, does not contaminate end products and is environmentally friendly.

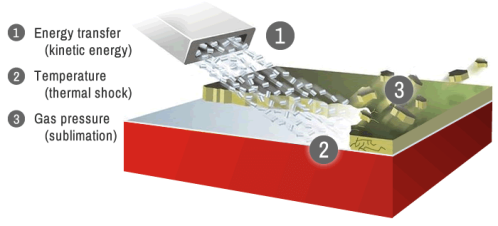

It is a process in which dry ice particles are propelled at high velocities to impact and clean a surface.The particles are accelerated by compressed air, just as with other blasting systems.

It depends on what you are cleaning. If you are removing a brittle contaminant such as paint, the process creates a compression tension wave between the coating and the substrate. This wave has enough energy to overcome the bonding strength and literally pop the coating off from the inside out. If you are removing a malleable or viscous coating such as oil, grease, or wax, the cleaning action is a flushing process similar to high pressure water. When the particles hit, they compress and mushroom out, creating a high velocity snow flow that actually flushes the surface.

Sandblasting is similar to using an ice pick, whereas dry ice blasting is similar to using a spatula. Sand cuts or chisels away the contaminant. Dry ice lifts it away.

It sublimates and returns to the atmosphere as carbon dioxide (CO2) gas. CO2 is a naturally occurring element that constitutes less than 1% of our atmosphere.

People sometimes think it disappears too, but it does not. All cleaning involves the relocation of dirt.When you mop a floor, the dirt moves from the floor to the mop, to the water in the bucket. With dry ice, the dirt moves from an undesirable area to an area where you can better deal with it. If it is a dry substance, it generally falls to the floor where it is swept away or vacuumed during normal maintenance. If it is a wet substance like grease, you take a methodical approach similar to hosing down a driveway. You start at one end and guide the grease to the other end or an exit point where it is wiped, vacuumed or squeegeed up.

No, but it does depends on the substrate. There is an energy threshold at which disbonding will occur and a threshold at which damage will occur. When the disbonding threshold is lower than the damage threshold, you can clean. If the reverse is true, damage can occur. Most of our applications deal with production equipment (cast iron, tool steel, tool grade aluminum etc), so there is no damage. We have incredible success with softer substrates such as plastics, wiring, pure copper, and fabrics, but these will be examined on a case-by-case basis.

Yes, the process cleans best hot. Most contaminants have weaker adhesive strength when hot. In many applications, you may be able to clean three to five times faster hot than cold. In addition, because dry ice sublimates on impact, entrapment of the blasting media is not an issue. Grit entrapment is an important reason those who clean with sand, walnut shells, or other grit media cannot clean online.

Yes, but generally not as much as you might think. The amount of cooling is dependent upon three main factors: mass of the targeted surface, dwell time, and ice usage rate.

Once again, it depends on the mass of the object you're blasting, your dry ice usage rate, and your dwell time. There will be condensation if you cool the substrate below the dewpoint (the dewpoint varies depending on local climate). Of course, if you're cleaning a hot mould it is rare to have condensation because you seldom cool the mould below the dewpoint. Condensation is not a factor most of the time. When it is, it can be dealt with quite easily. Use of a hot air knife can be highly effective.

It is made from liquid carbon dioxide. Dry ice exists as a liquid only under high pressure. When it drops to ambient pressure (the normal pressure that surrounds us), approximately half turns to gas and half turns to solid. The solid, usually in the form of fluffy snow, is then compressed to form dry ice blocks, pellets, or nuggets.

Pellets are made by taking liquid CO2 from a pressurized storage tank and dropping it to ambient pressure to produce snow. The snow is then pushed through a die to make pellets

Yes, however, the removal rate is dependent on a great many factors including: the underlying surface profile of the substrate; the thickness of the coating; the adhesive bond strength of the coating; and the cohesive strength of the coating (generally a function of age). Generally speaking, if you have concerns with contamination, toxic substances, waste disposal, or substrate damage, dry ice blasting should be considered as a cleaning option.

A methodical approach similar to hosing down a driveway is required if dry ice is to be effective on these and other wet contaminants. You must start at one end and work the grease to the other end where it can pass through a grate or be vacuumed or squeegeed for disposal. Some customers use a paper or plastic backdrop to catch the wet contaminant as it is removed from the substrate. Dry ice doesn't dissolve the oil and doesn't make it disappear so you must have an acceptable way of handling it when it is relocated by the blasting process.

It tends to remove the loosely adhered oxidation and salts, but will not remove the deeply adhered oxidation.

However (ASK US ABOUT OUR MIXED MEDIA BLAST THAT WILL REMOVE DEEP OXIDATION)

Yes. Noise is a function of air volume and air velocity. Within the nozzle, the stationary air is sheared by the high velocity air causing turbulence which creates noise. The level can range from 80 - 130 db. Hearing protection is required.

As long as it strikes the surface head on, dry ice does not ricochet because it sublimates (turns into a gas) on impact. As for the contaminant, you usually do not see or feel it as it disbonds and leaves the substrate, however, it is removed with some force which is why eye protection is necessary at all times.

As long as it strikes the surface head on, dry ice does not ricochet because it sublimates (turns into a gas) on impact. As for the contaminant, you usually do not see or feel it as it disbonds and leaves the substrate, however, it is removed with some force which is why eye protection is necessary at all times.